The green hydrogen era we have dreamed of turns into reality by SK ecoplant Project Nujio’qonik in Canada

The long-awaited realization of the “green hydrogen era” has finally arrived. Nujio’qonik, a global massive green hydrogen and ammonia commercialization project is ushering in a green hydrogen era. Let’s take a look.

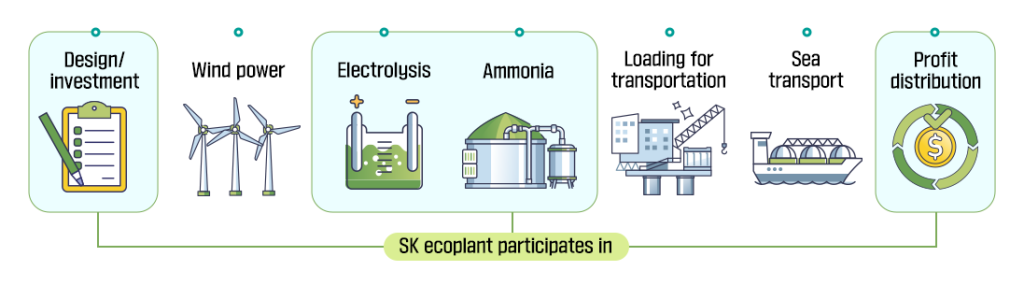

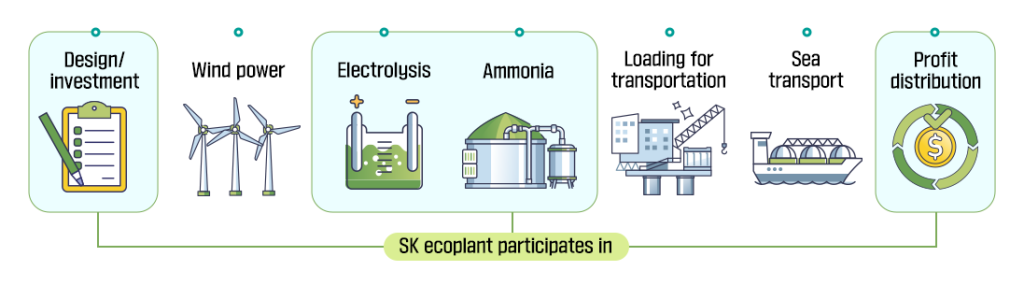

The project involves “producing green hydrogen from renewable energy sources, converting it into ammonia, and transporting it worldwide for use of hydrogen through energy conversion.” This comprehensive energy circulation system represents the collective aspiration of the world. SK ecoplant is transforming its green hydrogen value chain into reality.

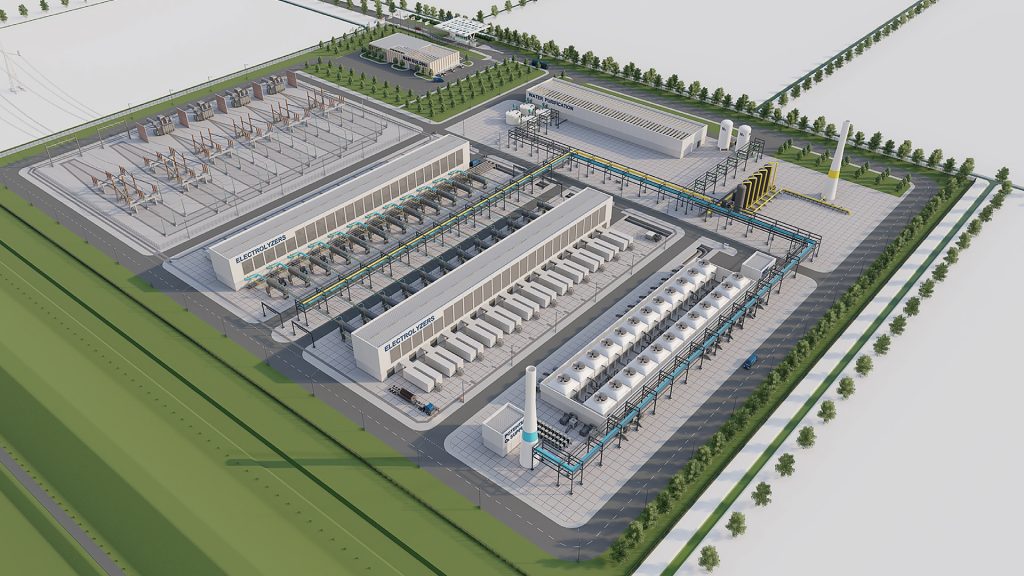

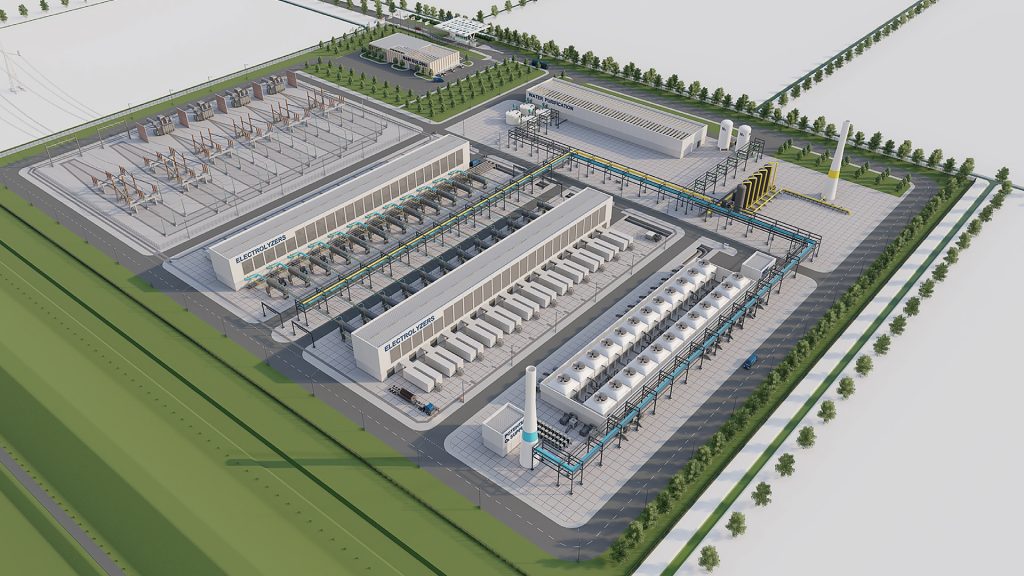

On May 17, SK ecoplant announced that it signed an MOU for participation in the first phase of Project Nujio’qonik, a massive green hydrogen commercialization project taking place in Canada. This project is led by World Energy Green Hydrogen2 (World Energy GH2), a joint venture of World Energy, and is executed in Newfoundland and Labrador, located Canada’s easternmost area. The project will be carried out in three phases with the $4.5 billion first phase targeting the generation of 1 GW of wind power from onshore wind farms, installation of 600 MW of *electrolysis cells, and the construction of a facility capable of producing 360,000 tons of *green ammonia. This ammonia will then be used to transport around 60,000 tons of green hydrogen produced at the site annually (starting in 2025 for green hydrogen production and 2026 for green ammonia production). This represents approximately 10% of Canada’s total ammonia production, making Canada the world’s 10th largest ammonia producer (As of 2020, Canada produced 3.9 million tons of ammonia a year. Source: investcanada)

* Electrolysis: a technique of using electricity to split water produce hydrogen with high purity. Hydrogen produced from renewable energy sources using electrolysis is referred to as “green hydrogen.”

* Green ammonia: ammonia produced by combining nitrogen and green hydrogen produced from renewable energy sources. Green ammonia is recognized as an effective method for transporting hydrogen that is difficult to be stored and transported.

SK ecoplant, a company specializing in green hydrogen, has taken a significant leap forward

SK ecoplant’s involvement in the project includes providing the *front-end engineering design (FEED) to establish the project’s overall framework, supplying and installing solid oxide electrolysis cells (SOEC), and undertaking the engineering, procurement, and construction (EPC) responsibilities for a green ammonia plant. Moreover, the company has invested in the project development, securing a 20% stake that will yield returns once the energy sources are commercialized. Additionally, the company is exploring the possibility of contributing to the construction of onshore wind farms.

* FEED: a process to minimize changes in the execution phase by designing basic engineering that incorporates requirements of a plant construction project, and to estimate rough investment costs and optimize them

With its “green hydrogen value chain”, SK ecoplant is poised to be a crucial partner in this project. The company has already established a business portfolio that spans the entire spectrum of the green hydrogen industry. Their expertise encompasses the development of renewable energy projects, installation of substructures for offshore wind power, SOEC technology with the highest efficiency, and establishment of green ammonia plants.

Furthermore, SK ecoplant has demonstrated its project development capabilities through successful participation in various large-scale global infrastructure projects in the U.K. and Norway. Their extensive experience in EPC instills trust, making them a supportive partner for World Energy. World Energy, a clean aviation fuel producer, has plans to expand its business into green hydrogen.

Competitiveness of Nujio’qonik where the sand blows

Canada, where Project Nujio’qonik is carried out, is one of the countries in the world known for its flourishing renewable energy industry thanks to its rich natural environment. As the world’s 7th largest producer of renewable energy in terms of production, Canada’s renewable energy accounts for 17.3% of its total energy production and 3% of the world’s energy generation (Source: KOTRA, as of 2021).

There is a reason why Canada is noteworthy. Canada is not just producing a large amount of renewable energy. The country has been committed to developing and implementing policies that foster the “hydrogen economy” with an aim to lead the global hydrogen market as “an exporter of renewable energy”. An example of this is the clean hydrogen investment tax credit introduced in March, which offers up to a 40% of tax credit for hydrogen production facilities and up to 15% for ammonia production facilities, provided that the production process generates 0.75-2 kg of carbon dioxide emissions for every 1kg of hydrogen produced. The credit is expected to drive significant growth not only for Project Nujio’qonik but also for Canada’s green hydrogen and ammonia market.

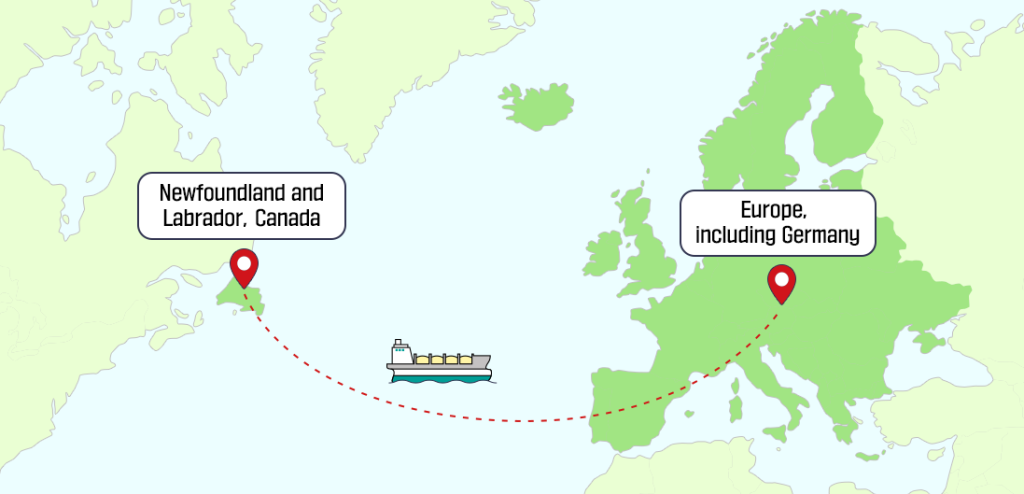

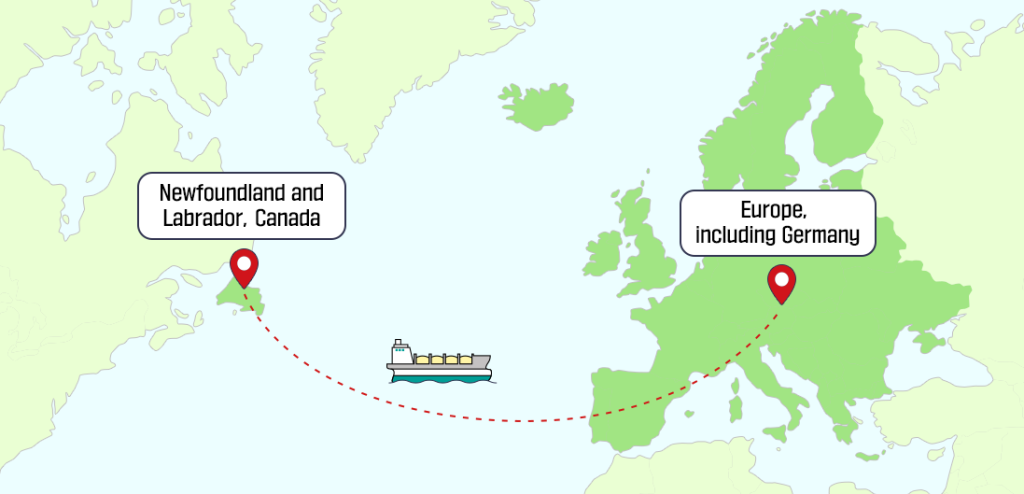

Moreover, Canada has already secured a substantial export market for its green hydrogen. In August of last year, the country signed an agreement with Germany to build up a “transatlantic supply chain” and plans to export Canadian-made hydrogen to Germany starting from 2025.

During the signing event, German Chancellor Olaf Scholz explained the rationale behind the agreement, stating that a significant portion of Germany’s future hydrogen demand is expected to be fulfilled through import from Canada. Germany’s emphasis on transitioning into a hydrogen economy, with a 9 billion euros investment in the hydrogen industry by 2030, indicates a high demand for hydrogen. Forecast shows the county will need 90-110 Twh of hydrogen by 2030, but it is projected to produce only 13-16% of its hydrogen requirements independently due to its natural environment (Source: Nationale Wasserstoffstrategie, 2020). Similarly, the country will need 18.2 million tons of ammonia (for hydrogen transportation and ship fuels) by 2030, but it can only produce 2.5 million tons (according to Deloitte estimates, 2023). Hence, Germany has chosen to position itself as a hydrogen importer rather than a hydrogen producer, and is actively seeking cooperation on hydrogen with various countries. Canada, given its geographical proximity and competitive pricing, is the most attractive partner for Germany. The cooperation between the two countries, coupled with their policy support is expected to significantly contribute to the successful execution of Project Nujio’qonik in which SK ecoplant is involved.

Canada’s favorable policies, diplomatic support, and advantageous geographic location have made it an ideal destination for green hydrogen and ammonia business. Consequently, the country is witnessing the emergence of multiple green hydrogen projects similar to Project Nujio’qonik. Among these projects, Project Nujio’qonik stands out due to its vast scale and rapid development, and aims to become Canada’s first commercial green hydrogen and ammonia producer.

Notably, the project’s location in Newfoundland, the easternmost region of Canada, offers abundant wind resources, which aligns with the project’s name, Nujio’qonik meaning “where the sand blows” in the Canadian native language. This wind-rich location ensures reliable wind power generation and convenient transportation to Europe, providing a competitive advantage to the project.

.

SK ecoplant’s green hydrogen value chain is set to expand worldwide

Through its participation in Project Nujio’qonik, SK ecoplant will showcase and validate its green hydrogen value chain, enhancing its visibility and establishing a business portfolio that encompasses all aspects of the green hydrogen industry including production, transportation, and utilization. Furthermore, SK ecoplant aims to incorporate Korean products in the *Balance of Plant (BOP) of SOECs installed in this project. This collaborative effort aims to foster the growth of the green hydrogen industry alongside Korean material, component, and equipment companies while also facilitating SK ecoplant’s global expansion.

* BOP (Balance of Plant): supporting and auxiliary components

Given that there have been no prior large-scale green hydrogen and ammonia commercialization projects in the world, Project Nujio’qonik holds immense significance for both SK ecoplant and the time we live in. Every “first” comes with its share of challenges, but overcoming them will establish a unique position and bring forth new opportunities. Let us anticipate the arrival of the green hydrogen era that SK ecoplant will usher in.

연관 콘텐츠

The green hydrogen era we have dreamed of turns into reality by SK ecoplant Project Nujio’qonik in Canada

The project involves “producing green hydrogen from renewable energy sources, converting it into ammonia, and transporting it worldwide for use of hydrogen through energy conversion.” This comprehensive energy circulation system represents the collective aspiration of the world. SK ecoplant is transforming its green hydrogen value chain into reality.

On May 17, SK ecoplant announced that it signed an MOU for participation in the first phase of Project Nujio’qonik, a massive green hydrogen commercialization project taking place in Canada. This project is led by World Energy Green Hydrogen2 (World Energy GH2), a joint venture of World Energy, and is executed in Newfoundland and Labrador, located Canada’s easternmost area. The project will be carried out in three phases with the $4.5 billion first phase targeting the generation of 1 GW of wind power from onshore wind farms, installation of 600 MW of *electrolysis cells, and the construction of a facility capable of producing 360,000 tons of *green ammonia. This ammonia will then be used to transport around 60,000 tons of green hydrogen produced at the site annually (starting in 2025 for green hydrogen production and 2026 for green ammonia production). This represents approximately 10% of Canada’s total ammonia production, making Canada the world’s 10th largest ammonia producer (As of 2020, Canada produced 3.9 million tons of ammonia a year. Source: investcanada)

* Electrolysis: a technique of using electricity to split water produce hydrogen with high purity. Hydrogen produced from renewable energy sources using electrolysis is referred to as “green hydrogen.”

* Green ammonia: ammonia produced by combining nitrogen and green hydrogen produced from renewable energy sources. Green ammonia is recognized as an effective method for transporting hydrogen that is difficult to be stored and transported.

SK ecoplant, a company specializing in green hydrogen, has taken a significant leap forward

SK ecoplant’s involvement in the project includes providing the *front-end engineering design (FEED) to establish the project’s overall framework, supplying and installing solid oxide electrolysis cells (SOEC), and undertaking the engineering, procurement, and construction (EPC) responsibilities for a green ammonia plant. Moreover, the company has invested in the project development, securing a 20% stake that will yield returns once the energy sources are commercialized. Additionally, the company is exploring the possibility of contributing to the construction of onshore wind farms.

* FEED: a process to minimize changes in the execution phase by designing basic engineering that incorporates requirements of a plant construction project, and to estimate rough investment costs and optimize them

With its “green hydrogen value chain”, SK ecoplant is poised to be a crucial partner in this project. The company has already established a business portfolio that spans the entire spectrum of the green hydrogen industry. Their expertise encompasses the development of renewable energy projects, installation of substructures for offshore wind power, SOEC technology with the highest efficiency, and establishment of green ammonia plants.

Furthermore, SK ecoplant has demonstrated its project development capabilities through successful participation in various large-scale global infrastructure projects in the U.K. and Norway. Their extensive experience in EPC instills trust, making them a supportive partner for World Energy. World Energy, a clean aviation fuel producer, has plans to expand its business into green hydrogen.

Competitiveness of Nujio’qonik where the sand blows

Canada, where Project Nujio’qonik is carried out, is one of the countries in the world known for its flourishing renewable energy industry thanks to its rich natural environment. As the world’s 7th largest producer of renewable energy in terms of production, Canada’s renewable energy accounts for 17.3% of its total energy production and 3% of the world’s energy generation (Source: KOTRA, as of 2021).

There is a reason why Canada is noteworthy. Canada is not just producing a large amount of renewable energy. The country has been committed to developing and implementing policies that foster the “hydrogen economy” with an aim to lead the global hydrogen market as “an exporter of renewable energy”. An example of this is the clean hydrogen investment tax credit introduced in March, which offers up to a 40% of tax credit for hydrogen production facilities and up to 15% for ammonia production facilities, provided that the production process generates 0.75-2 kg of carbon dioxide emissions for every 1kg of hydrogen produced. The credit is expected to drive significant growth not only for Project Nujio’qonik but also for Canada’s green hydrogen and ammonia market.

Moreover, Canada has already secured a substantial export market for its green hydrogen. In August of last year, the country signed an agreement with Germany to build up a “transatlantic supply chain” and plans to export Canadian-made hydrogen to Germany starting from 2025.

During the signing event, German Chancellor Olaf Scholz explained the rationale behind the agreement, stating that a significant portion of Germany’s future hydrogen demand is expected to be fulfilled through import from Canada. Germany’s emphasis on transitioning into a hydrogen economy, with a 9 billion euros investment in the hydrogen industry by 2030, indicates a high demand for hydrogen. Forecast shows the county will need 90-110 Twh of hydrogen by 2030, but it is projected to produce only 13-16% of its hydrogen requirements independently due to its natural environment (Source: Nationale Wasserstoffstrategie, 2020). Similarly, the country will need 18.2 million tons of ammonia (for hydrogen transportation and ship fuels) by 2030, but it can only produce 2.5 million tons (according to Deloitte estimates, 2023). Hence, Germany has chosen to position itself as a hydrogen importer rather than a hydrogen producer, and is actively seeking cooperation on hydrogen with various countries. Canada, given its geographical proximity and competitive pricing, is the most attractive partner for Germany. The cooperation between the two countries, coupled with their policy support is expected to significantly contribute to the successful execution of Project Nujio’qonik in which SK ecoplant is involved.

Canada’s favorable policies, diplomatic support, and advantageous geographic location have made it an ideal destination for green hydrogen and ammonia business. Consequently, the country is witnessing the emergence of multiple green hydrogen projects similar to Project Nujio’qonik. Among these projects, Project Nujio’qonik stands out due to its vast scale and rapid development, and aims to become Canada’s first commercial green hydrogen and ammonia producer.

Notably, the project’s location in Newfoundland, the easternmost region of Canada, offers abundant wind resources, which aligns with the project’s name, Nujio’qonik meaning “where the sand blows” in the Canadian native language. This wind-rich location ensures reliable wind power generation and convenient transportation to Europe, providing a competitive advantage to the project.

.

SK ecoplant’s green hydrogen value chain is set to expand worldwide

Through its participation in Project Nujio’qonik, SK ecoplant will showcase and validate its green hydrogen value chain, enhancing its visibility and establishing a business portfolio that encompasses all aspects of the green hydrogen industry including production, transportation, and utilization. Furthermore, SK ecoplant aims to incorporate Korean products in the *Balance of Plant (BOP) of SOECs installed in this project. This collaborative effort aims to foster the growth of the green hydrogen industry alongside Korean material, component, and equipment companies while also facilitating SK ecoplant’s global expansion.

* BOP (Balance of Plant): supporting and auxiliary components

Given that there have been no prior large-scale green hydrogen and ammonia commercialization projects in the world, Project Nujio’qonik holds immense significance for both SK ecoplant and the time we live in. Every “first” comes with its share of challenges, but overcoming them will establish a unique position and bring forth new opportunities. Let us anticipate the arrival of the green hydrogen era that SK ecoplant will usher in.